Aspects associated with a calibration sleeve

2024-02-29

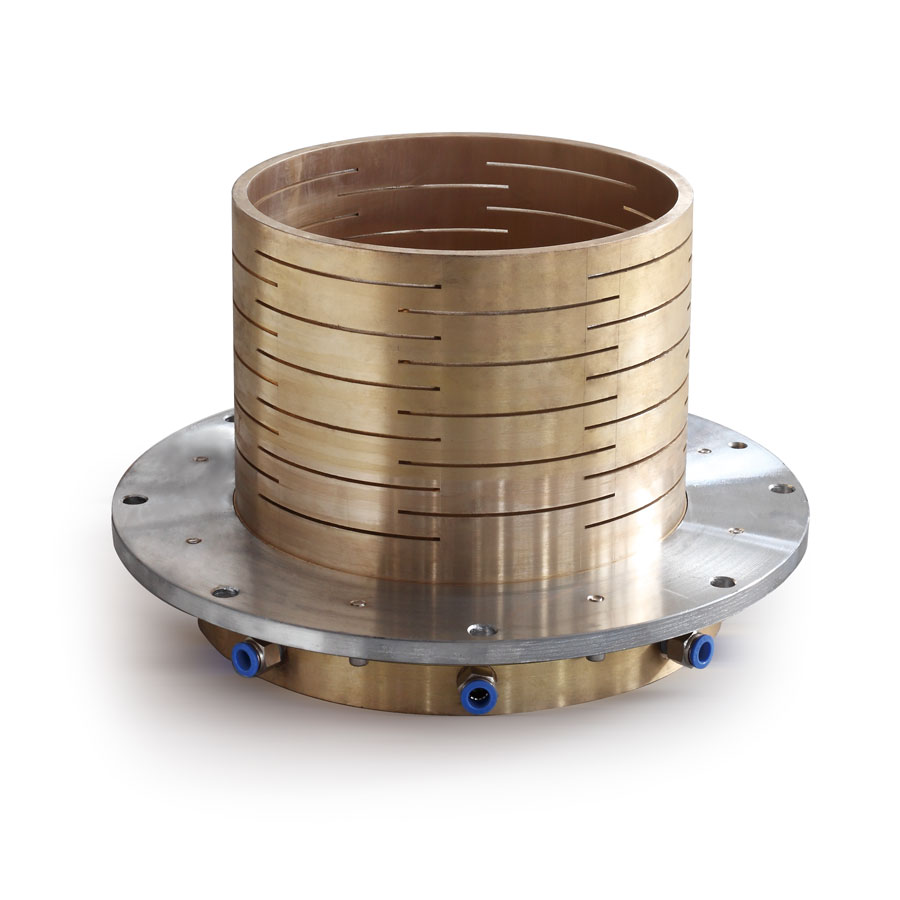

A calibration sleeve is an essential component in the plastic extrusion process, specifically in the calibration or sizing stage. It is part of the downstream equipment used to shape, size, and cool the extruded plastic material after it passes through the extrusion die and vacuum calibration water tank. Here are key aspects associated with a calibration sleeve:

1. Extrusion Process:

- The calibration sleeve is used in the plastic extrusion line, where raw plastic material is melted and forced through a die to form a specific shape.

2. Calibration or Sizing Stage:

- After leaving the vacuum calibration water tank, the extruded material enters the calibration sleeve for further sizing and shaping. This stage is crucial for achieving the desired product dimensions and characteristics.

3. Material Compatibility:

- The calibration sleeve is designed to be compatible with various plastic materials commonly used in extrusion processes. Different materials may require specific calibration conditions.

4. Sleeve Design:

- The sleeve is custom-designed to match the shape and dimensions of the extruded profile. It plays a key role in determining the final size and shape of the extruded product.

5. Temperature Control:

- Temperature control systems may be incorporated to regulate the temperature of the calibration sleeve. Maintaining the right temperature is essential for the sizing process.

6. Adjustable Sizing:

- The calibration sleeve may have adjustable sizing mechanisms to control the dimensions of the extruded product. This is important for achieving the desired product specifications.

7. Water or Cooling Medium Circulation:

- The calibration sleeve is equipped with a circulation system for a cooling medium, such as water. This ensures efficient cooling of the extruded material, setting its shape and dimensions.

8. Conveyor System:

- A conveyor system is often integrated into the calibration sleeve to support the extruded material as it passes through the calibration stage.

9. Monitoring and Control:

- The sleeve may include monitoring and control systems to oversee parameters such as temperature, sizing adjustments, and the overall calibration process.

10. Adjustable Water Flow:

- The water flow in the calibration sleeve is adjustable to control the cooling rate and ensure uniform cooling across the entire extruded profile.

11. Material Handling:

- The design of the calibration sleeve considers the handling of the extruded material, ensuring it moves smoothly through the calibration stage.

12. Durability and Corrosion Resistance:

- Given the continuous exposure to water or cooling medium, the calibration sleeve is typically made from materials that are durable and resistant to corrosion.

13. Accessibility for Maintenance:

- Easy access points and design features are incorporated to facilitate maintenance and cleaning of the calibration sleeve.

14. Integration with Extrusion Line:

- The calibration sleeve is seamlessly integrated into the overall extrusion line, working in conjunction with other downstream equipment and components.

The calibration sleeve is a critical component for achieving precise dimensions and the desired quality in plastic extrusions. Its design and features may vary based on the specific requirements of the extrusion process and the type of plastic products being manufactured.