Benefits of Oil-Free Screw Blowers

2024-04-29

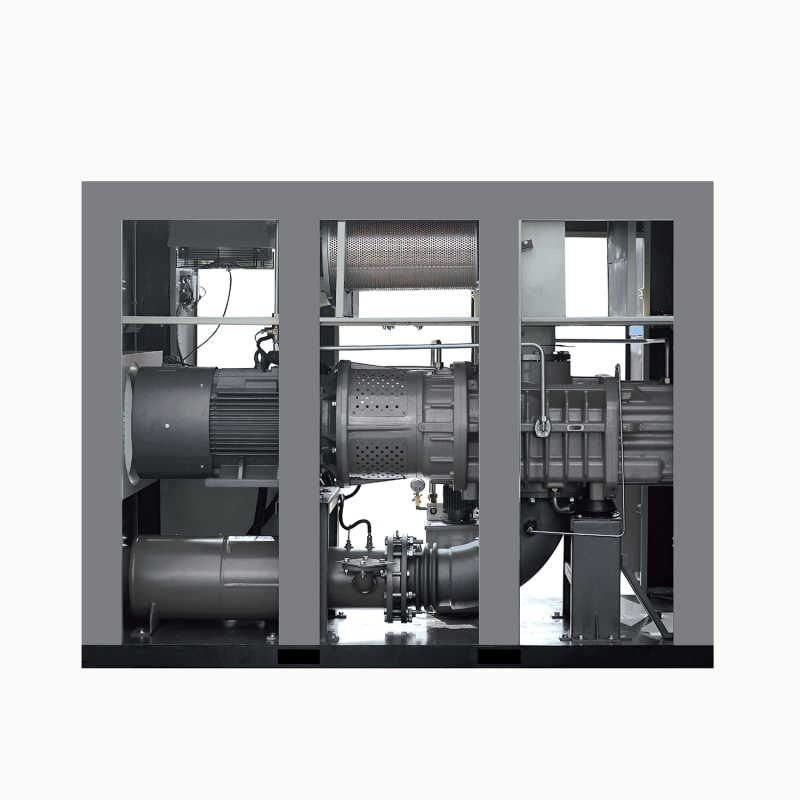

Oil-free screw blowers are innovative machines used in various industrial applications for the compression of air and gases. Unlike traditional screw blowers, which require lubrication with oil for sealing and cooling, oil-free screw blowers employ advanced design features to eliminate the need for oil lubrication. Here are some key features and benefits of oil-free screw blowers:

1. Dry Compression: Oil-free screw blowers achieve compression without the use of oil lubrication. This dry compression technology eliminates the risk of oil contamination in the compressed air or gas stream, making them suitable for applications where oil-free operation is essential, such as food and beverage processing, pharmaceutical production, and electronics manufacturing.

2. Advanced Sealing Mechanisms: Oil-free screw blowers utilize specialized sealing mechanisms to maintain internal pressure and prevent air or gas leakage without the need for oil lubrication. Common sealing techniques include labyrinth seals, carbon ring seals, and Teflon-coated components, which provide reliable sealing performance and durability.

3. Efficiency and Energy Savings: Oil-free screw blowers are designed for high efficiency and energy savings compared to traditional oil-lubricated blowers. By eliminating the need for oil lubrication, they reduce frictional losses, minimize energy consumption, and lower operating costs over the lifetime of the equipment. Variable speed drive (VSD) technology further enhances energy efficiency by matching the blower's output to the demand, optimizing performance under varying operating conditions.

4. Low Maintenance Requirements: The absence of oil lubrication simplifies maintenance and reduces downtime associated with oil changes, filter replacements, and oil disposal. Oil-free screw blowers typically have longer service intervals and require minimal maintenance, resulting in increased productivity and reduced total cost of ownership.

5. Clean and Environmentally Friendly: Oil-free screw blowers produce clean, oil-free compressed air or gas that meets stringent quality standards for various industrial processes. They help maintain product purity and integrity in sensitive applications where oil contamination is unacceptable. Additionally, the elimination of oil lubrication reduces the environmental impact associated with oil usage, spills, and disposal, making them environmentally friendly alternatives.

6. Compact Design: Oil-free screw blowers are often designed with compact footprints and modular configurations to maximize space efficiency and installation flexibility. Their compact design allows for easy integration into existing systems or installation in space-constrained environments, minimizing installation costs and infrastructure requirements.

7. Quiet Operation: Advanced noise reduction technologies, such as optimized rotor profiles, vibration dampening, and sound-insulated enclosures, ensure quiet operation of oil-free screw blowers. Reduced noise levels improve workplace safety and comfort, making them suitable for indoor installations and noise-sensitive environments.

8. Versatility: Oil-free screw blowers are versatile machines capable of handling a wide range of air and gas compression applications, including pneumatic conveying, wastewater treatment, aeration, vacuum generation, and more. They offer flexibility in performance, flow rates, and pressure ranges to meet the specific requirements of different industries and processes.

Overall, oil-free screw blowers provide reliable, efficient, and environmentally friendly compressed air and gas solutions for a diverse range of industrial applications. Their innovative design features, combined with superior performance and low maintenance requirements, make them preferred choices for businesses seeking sustainable and cost-effective compressed air solutions.