Chipboard Screws: The Perfect Fasteners for Woodworking and Furniture Assembly

2025-06-18

When it comes to woodworking and furniture assembly, choosing the right screw can make all the difference between a sturdy piece and a flimsy one. Chipboard screws are specifically designed for fastening particle board, chipboard, MDF, and other engineered wood materials. If you’re a DIY enthusiast, carpenter, or manufacturer, understanding the features and benefits of chipboard screws will help you get the best results for your projects.

What Are Chipboard Screws?

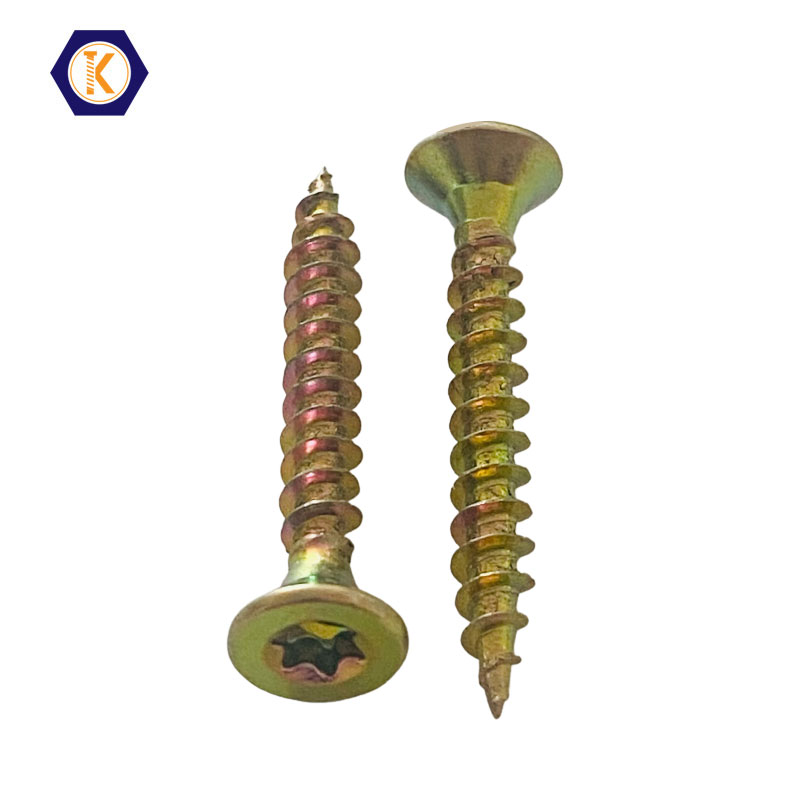

Chipboard screws are specialized screws engineered with coarse threads and sharp points to provide strong holding power in chipboard and similar materials. Unlike standard wood screws, chipboard screws are designed to reduce splitting and ensure a firm grip in composite woods that can be prone to crumbling or damage.

Key Features of Chipboard Screws

Coarse Threads

The wide, deep threads grip the soft composite material securely, preventing the screw from loosening over time.

Sharp Point

Designed for self-drilling, the sharp tip reduces the need for pre-drilling pilot holes, saving time and effort.

Flat or Countersunk Head

Allows the screw to sit flush with or below the wood surface for a neat finish.

Durable Materials

Often made from steel with coatings like zinc plating or black phosphate for corrosion resistance.

Where Are Chipboard Screws Commonly Used?

Furniture Assembly

Ideal for flat-pack furniture where particle board is commonly used.

Cabinet Making

Securely fasten cabinet panels without splitting the composite wood.

DIY Wood Projects

Perfect for hobbyists working with MDF or chipboard sheets.

Interior Fixtures

Used for shelves, wardrobes, and partitions where engineered wood is the main material.

Advantages of Using Chipboard Screws

Strong Holding Power in softer materials, reducing the chance of loosening.

Reduced Material Damage thanks to their self-tapping design.

Time-Saving by eliminating or minimizing pilot hole drilling.

Versatility across many engineered wood products.

Tips for Using Chipboard Screws

Pre-Drill When Necessary: For thicker or very dense boards, a small pilot hole can still help prevent cracking.

Avoid Over-Tightening: Too much torque can strip the threads or damage the wood.

Choose the Right Length: Ensure the screw is long enough to penetrate the material but not so long it pokes through.

Select Proper Coating: Use coated screws in humid areas to prevent rust.

Final Thoughts

Whether you’re putting together a new bookshelf or building custom furniture, chipboard screws provide a reliable, efficient fastening solution tailored for engineered wood materials. Their specialized design ensures strong joints and lasting durability, making them a must-have for any woodworking toolkit.