Coating Machines: Revolutionizing Manufacturing Processes

2025-03-05

Coating machines play a crucial role in modern manufacturing, providing an efficient and effective way to apply coatings to various surfaces. From industrial products to consumer goods, the applications of coating machines are vast and continue to evolve with advancements in technology. These machines are designed to ensure a consistent and high-quality finish, which is essential for both aesthetic appeal and durability. In this blog, we will explore the importance of coating machines, their types, applications, and the benefits they bring to industries around the world.

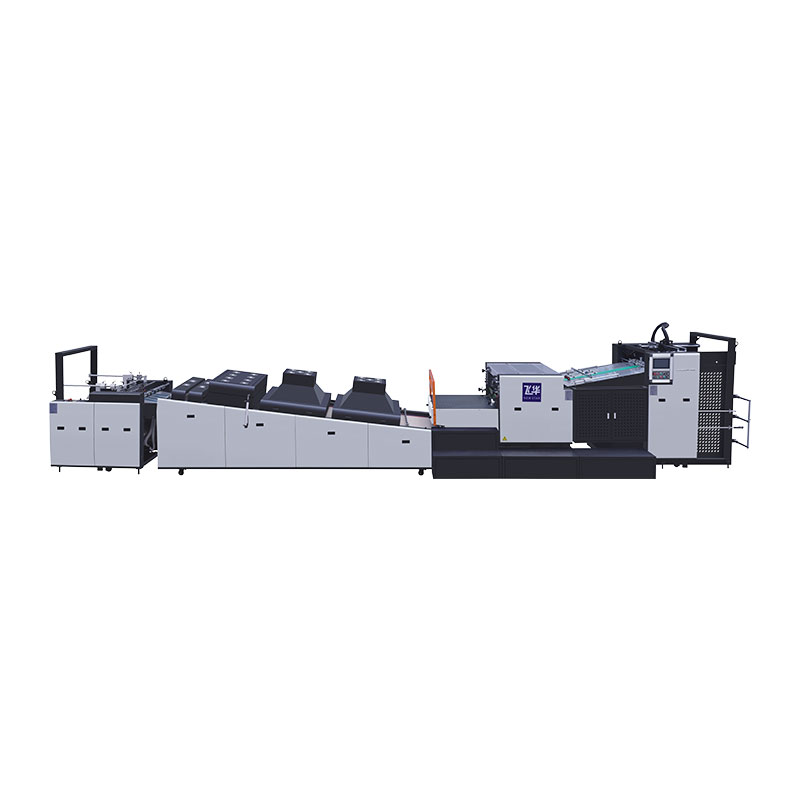

What Are Coating Machines?

Coating machines are devices used to apply a protective or decorative layer on the surface of materials such as metals, plastics, fabrics, and paper. These machines use various methods to apply coatings, including spraying, dipping, brushing, or roller coating, depending on the material and the type of finish required.

Coating machines are widely used in a range of industries, from automotive and electronics to packaging and textiles. They ensure that the finished product meets both functional and aesthetic standards. The coatings applied by these machines can offer protection against corrosion, wear, moisture, UV radiation, and other environmental factors, while also improving the product's appearance.

Types of Coating Machines

1. Spray Coating Machines

Spray coating machines use a nozzle to atomize a coating material, which is then sprayed onto the surface of the product. These machines are versatile and can be used for a variety of materials, including metals, plastics, and ceramics. Spray coating is ideal for covering large or complex surfaces and is commonly used in industries such as automotive manufacturing and electronics.

2. Dip Coating Machines

Dip coating machines immerse the substrate into a tank containing the coating material. Once the object is submerged, it is withdrawn, and the excess coating is removed, leaving a uniform layer on the surface. This method is particularly useful for coating parts with intricate shapes or for creating thicker coatings. Dip coating is often used in the production of wires, tools, and hardware.

3. Roller Coating Machines

Roller coating involves applying the coating material using rollers that press the material onto the substrate. This technique is typically used for large, flat surfaces and is common in industries such as paper production and flooring manufacturing. Roller coating is known for its efficiency, as it allows for a high-speed application process with minimal waste.

4. Brush Coating Machines

Brush coating machines use brushes to apply a thin layer of coating material to the surface. This method is often employed for smaller, more detailed projects where precision is crucial. Brush coating machines are commonly used in industries such as woodworking, metalworking, and furniture manufacturing.

5. Electrostatic Coating Machines

Electrostatic coating machines use an electric charge to attract the coating material to the surface of the product. This method ensures that the coating adheres evenly and efficiently, even on complex shapes. Electrostatic coating is commonly used for automotive parts and metal finishing due to its ability to reduce waste and achieve a smooth, uniform finish.

Applications of Coating Machines

Coating machines are used across a wide range of industries, each benefiting from their unique capabilities. Here are some of the key sectors where coating machines are essential:

1. Automotive Industry

In the automotive industry, coating machines are used to apply protective coatings to vehicle parts, including car bodies, wheels, and interior components. These coatings protect against corrosion, wear, and environmental damage while enhancing the aesthetic appeal of the vehicles. For instance, automotive manufacturers often use powder coating machines for a durable and long-lasting finish.

2. Electronics and Electrical Components

Coating machines are critical in the electronics industry, where they are used to apply protective coatings to circuit boards, connectors, and other electronic components. These coatings prevent moisture, dust, and corrosion from affecting the performance of electrical parts. Conformal coating machines, for example, provide a protective layer on printed circuit boards (PCBs) to ensure their longevity and reliability.

3. Packaging Industry

Coating machines are commonly used in the packaging industry to apply protective or decorative coatings to materials such as cardboard, plastic, and metal. These coatings can enhance the appearance of packaging, making products more appealing to consumers, while also providing a protective layer that prevents damage during transport.

4. Textile Industry

In the textile industry, coating machines are used to apply finishes to fabrics. This can include water-repellent coatings, flame-retardant treatments, or decorative patterns. Coating machines can improve the functionality and durability of fabrics, making them suitable for a variety of applications, including clothing, upholstery, and industrial textiles.

5. Food and Beverage Industry

The food industry also benefits from coating machines, particularly in the application of coatings to food packaging materials. These coatings help preserve the freshness of food, prevent contamination, and enhance shelf life. Additionally, coating machines are used for food processing, such as applying edible coatings to fruits and vegetables to extend their freshness.

Benefits of Coating Machines

1. Improved Durability and Protection

One of the primary benefits of coating machines is their ability to enhance the durability and longevity of products. By applying protective coatings, manufacturers can safeguard products from environmental damage, wear, corrosion, and moisture. This is especially crucial in industries like automotive manufacturing, electronics, and construction, where durability is key to product performance.

2. Enhanced Aesthetic Appeal

Coatings can dramatically improve the appearance of a product, adding color, gloss, and texture. This is particularly important in consumer products such as furniture, electronics, and packaging. A well-applied coating can make a product look more attractive and help it stand out in a competitive market.

3. Efficiency and Cost Savings

Coating machines allow for faster and more efficient production processes. By automating the coating process, manufacturers can reduce labor costs, minimize errors, and ensure consistent results. The use of coating machines can also reduce material waste, as they provide more precise and controlled application compared to manual methods.

4. Customization and Versatility

Coating machines offer a high level of customization. Depending on the type of coating machine and the material being coated, manufacturers can apply a wide range of finishes, from matte to glossy, and even create specialized coatings with unique properties, such as anti-bacterial or anti-corrosion features.

Conclusion

Coating machines are indispensable in modern manufacturing, providing both functional and aesthetic benefits to a wide array of industries. Whether it’s enhancing durability, improving appearance, or streamlining production processes, coating machines offer a versatile solution for many different types of products. As technology continues to advance, we can expect even more innovative and efficient coating solutions that will further revolutionize manufacturing practices and improve the quality of the products we use every day.