Considerations related to steel wire rope slings

2023-11-16

Steel wire rope slings are lifting assemblies made from steel cables and are commonly used in material handling and lifting applications. They provide a flexible and strong means of lifting, hoisting, or securing loads in various industries, including construction, manufacturing, shipping, and logistics. Steel wire rope slings are designed to handle heavy loads and offer advantages such as durability, flexibility, and resistance to abrasion. Here are key features and considerations related to steel wire rope slings:

1. Construction:

- Steel wire rope slings are constructed from multiple strands of steel wires twisted or braided together. The construction and design of the sling depend on factors such as the intended use, load capacity, and environmental conditions.

2. Types of Steel Wire Rope Slings:

- Common types of steel wire rope slings include:

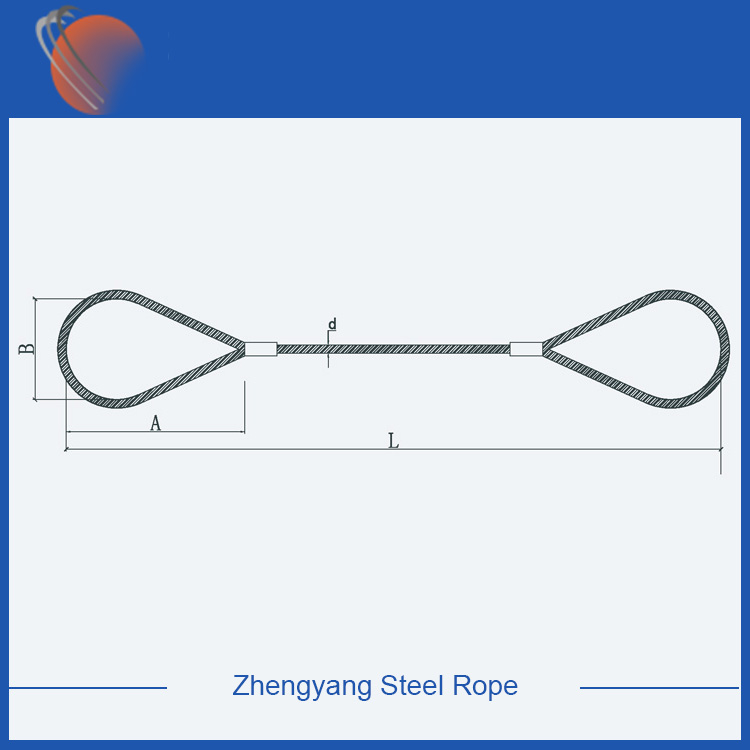

- Single-Part Slings: Consist of one continuous length of wire rope with end terminations (such as eye hooks).

- Multi-Part Slings: Comprise multiple parallel wire ropes with end terminations. Common configurations include 2-leg, 3-leg, and 4-leg slings.

3. End Terminations:

- Steel wire rope slings are typically fitted with end terminations, such as thimbles, hooks, eyes, or other fittings, to facilitate attachment to hooks, hoists, or lifting points.

4. Load Capacity and Working Load Limit (WLL):

- The load capacity of a steel wire rope sling is determined by factors like the diameter and construction of the wire rope. The Working Load Limit (WLL) specifies the maximum load a sling is designed to handle safely. It is important to ensure that the WLL of the sling meets or exceeds the intended load requirements.

5. Flexibility:

- Steel wire rope slings are flexible, allowing them to conform to the shape of the load and provide secure lifting. The flexibility of the sling contributes to its versatility in various lifting applications.

6. Durability and Resistance:

- Steel wire ropes are known for their durability and resistance to abrasion, making them suitable for demanding lifting conditions. The galvanized or coated options further enhance resistance to corrosion.

7. Inspection and Maintenance:

- Regular inspection and maintenance are crucial for ensuring the safety and reliability of steel wire rope slings. Inspections should include checking for wear, broken wires, deformations, and proper termination fittings.

8. Environmental Considerations:

- The choice of steel wire rope sling may be influenced by environmental conditions. For example, galvanized or coated slings are suitable for outdoor or corrosive environments.

9. Storage:

- Proper storage practices help prevent damage to steel wire rope slings. They should be stored in a dry, cool place, and care should be taken to avoid kinks, twists, or sharp bends.

10. Regulatory Compliance:

- Steel wire rope slings must comply with industry standards and regulations, such as those set by organizations like OSHA (Occupational Safety and Health Administration) in the United States.

11. Usage Guidelines:

- Steel wire rope slings should be used in accordance with the manufacturer's guidelines and recommendations for safe lifting practices.

Steel wire rope slings are versatile and widely used in various industries for lifting and handling heavy loads. Proper selection, usage, and maintenance of steel wire rope slings are essential to ensure safety and efficiency in lifting operations.