Features and considerations for LED plastic tube housings

2024-04-15

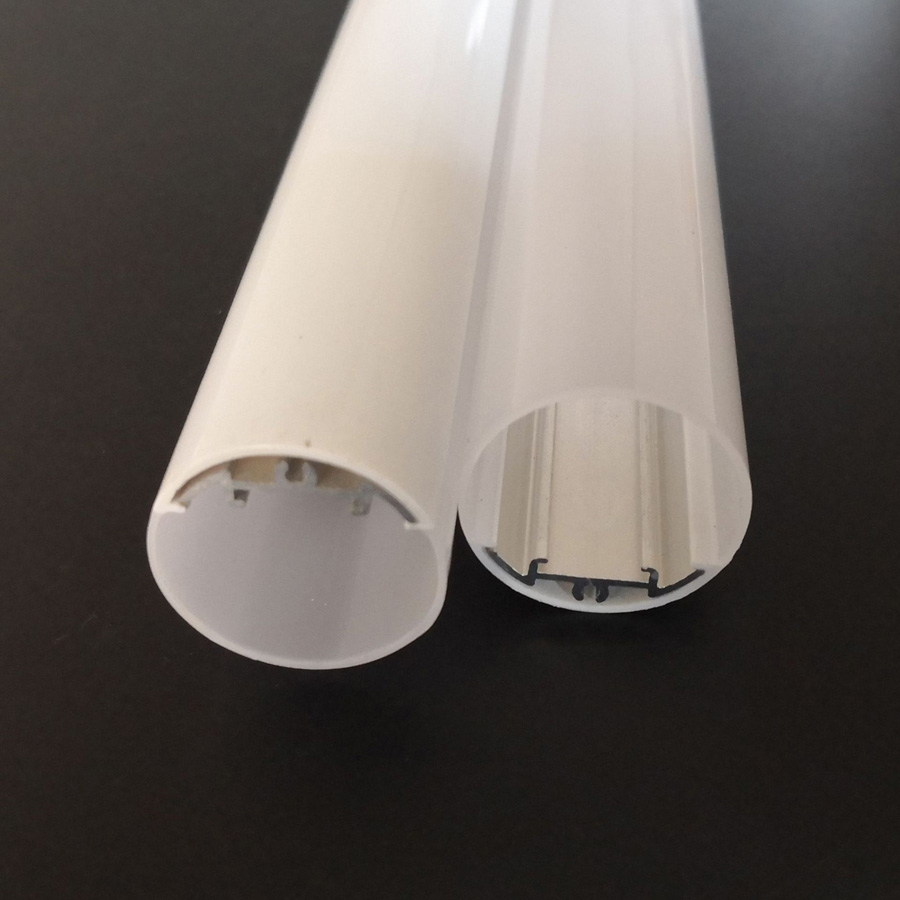

LED plastic tube housing refers to the protective casing or enclosure used to house LED (Light Emitting Diode) tubes. These housings are typically made from plastic materials and are designed to provide structural support, protection, and diffusion for the LED tubes. Here are some key features and considerations for LED plastic tube housings:

1. Material: LED plastic tube housings are commonly made from polycarbonate or acrylic plastic materials. These materials are lightweight, durable, and resistant to impact, making them suitable for protecting LED tubes from damage during installation, handling, and operation.

2. Design: LED plastic tube housings come in various designs and configurations to accommodate different types and sizes of LED tubes. They may feature a cylindrical or rectangular shape, with end caps or connectors for easy installation and connection to power sources.

3. Translucency: LED plastic tube housings are often translucent or diffused to help distribute light evenly along the length of the tube. Translucent housings help to minimize glare, reduce hot spots, and create a more uniform lighting effect, enhancing the visual appeal and functionality of the LED tubes.

4. Protection: LED plastic tube housings provide protection for LED tubes against dust, moisture, and physical damage. They help to seal and encapsulate the LED tubes, shielding them from environmental elements and prolonging their lifespan in indoor and outdoor applications.

5. Heat Dissipation: Some LED plastic tube housings are designed with ventilation slots or heat dissipation features to help dissipate heat generated by the LED tubes during operation. Effective heat dissipation helps to prevent overheating and ensures the long-term reliability and performance of the LED lighting system.

6. Installation: LED plastic tube housings are designed for easy installation and can be mounted on ceilings, walls, or suspended from overhead structures using mounting brackets, clips, or screws. They may also feature integrated connectors or wiring terminals for quick and secure electrical connections.

7. Customization: LED plastic tube housings can be customized with different colors, finishes, and patterns to match the aesthetic preferences or branding requirements of the application. Customization options may include color-matching, printing, or embossing of logos, text, or graphics on the housing surface.

8. Compliance: LED plastic tube housings should comply with relevant safety standards and regulations for electrical and lighting products, such as UL (Underwriters Laboratories) certification in the United States or CE (Conformité Européenne) marking in the European Union. Compliance ensures that the housings meet quality, performance, and safety requirements for use in commercial, industrial, and residential settings.

Overall, LED plastic tube housings play a crucial role in protecting, diffusing, and enhancing the performance of LED tubes in various lighting applications. By considering factors such as material, design, translucency, protection, heat dissipation, installation, customization, and compliance, you can select the right LED plastic tube housing to meet the specific requirements of your lighting project or application.