High Voltage Insulators: Ensuring Safety and Efficiency in Power Systems

2025-03-20

High voltage power transmission is essential for delivering electricity over long distances. However, managing high voltage comes with significant challenges, such as preventing electrical leakage and ensuring system safety. This is where high voltage insulators play a crucial role. Designed to withstand extreme electrical stress, these insulators ensure the efficient and safe operation of power systems.

What Are High Voltage Insulators?

High voltage insulators are non-conductive materials used to support and separate electrical conductors in power transmission and distribution systems. Their primary function is to prevent unwanted current flow, ensuring that electricity travels through the intended pathways without causing short circuits or power failures.

Types of High Voltage Insulators

1. Pin Insulators

- Used in low to medium-voltage transmission lines.

- Mounted on poles to support conductors and prevent current leakage.

2. Suspension Insulators

- Commonly used in high voltage transmission lines (above 33kV).

- Consist of multiple insulator discs connected in a string, allowing flexibility and better load distribution.

3. Strain Insulators

- Designed for high-tension applications where conductors experience mechanical stress.

- Typically used at dead-end poles or sharp transmission line angles.

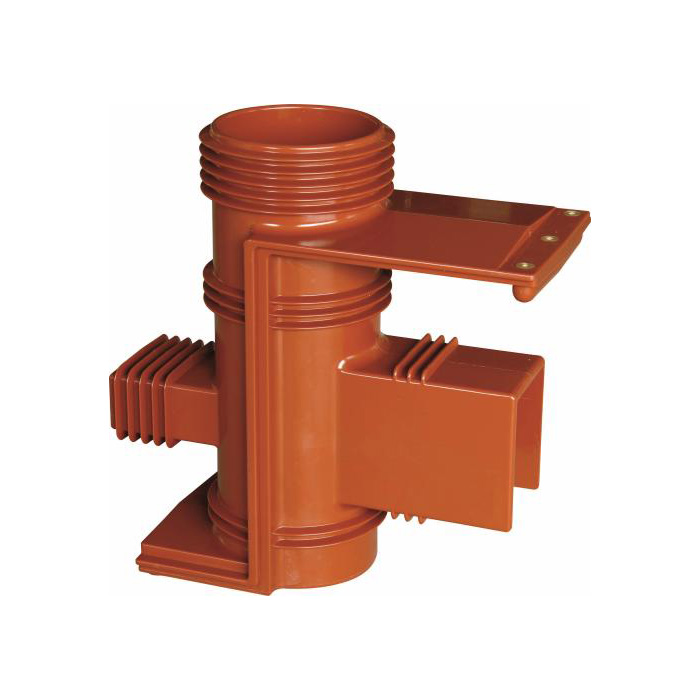

4. Post Insulators

- Used in substations and high voltage switchgear.

- Can withstand vertical and horizontal loads, ensuring stability.

5. Shackle Insulators

- Found in low-voltage distribution networks.

- Provide support at sharp bends or terminations in electrical lines.

Materials Used in High Voltage Insulators

1. Porcelain Insulators

- Made from ceramic materials.

- Highly durable and resistant to environmental factors.

- Used in high-voltage transmission and distribution lines.

2. Glass Insulators

- Offer excellent dielectric strength and resistance to mechanical stress.

- More resistant to aging and cracking than porcelain.

3. Polymer (Composite) Insulators

- Made from silicone rubber or epoxy resin, reinforced with fiberglass.

- Lightweight, shatter-resistant, and resistant to pollution and moisture.

- Increasingly used in modern high-voltage transmission systems.

Importance of High Voltage Insulators

Prevent Electrical Leakage

Insulators block unintended current flow, ensuring that electricity follows the correct path.

Enhance Safety

They protect workers, equipment, and infrastructure from electrical hazards and failures.

Improve System Efficiency

By minimizing energy loss, insulators contribute to a more reliable power supply.

Resist Harsh Environmental Conditions

High voltage insulators are designed to withstand rain, dust, UV radiation, and pollution, ensuring long-term performance.

Choosing the Right High Voltage Insulator

When selecting a high voltage insulator, consider:

- Voltage Level: Ensure the insulator is rated for the required voltage.

- Environmental Conditions: Consider pollution, humidity, and temperature variations.

- Mechanical Strength: Choose an insulator that can handle the tension and weight of the conductors.

- Material Type: Polymer insulators are ideal for lightweight applications, while porcelain and glass are preferred for extreme durability.

Final Thoughts

High voltage insulators are essential for maintaining the safety, efficiency, and reliability of power transmission and distribution networks. Choosing the right insulator prevents power failures, extends equipment lifespan, and ensures a stable electricity supply.

Looking for High-Quality High Voltage Insulators?

Explore durable and efficient high voltage insulators that meet industry standards and ensure reliable power distribution.