Key Features of Slant-Bed CNC Lathes

2024-05-21

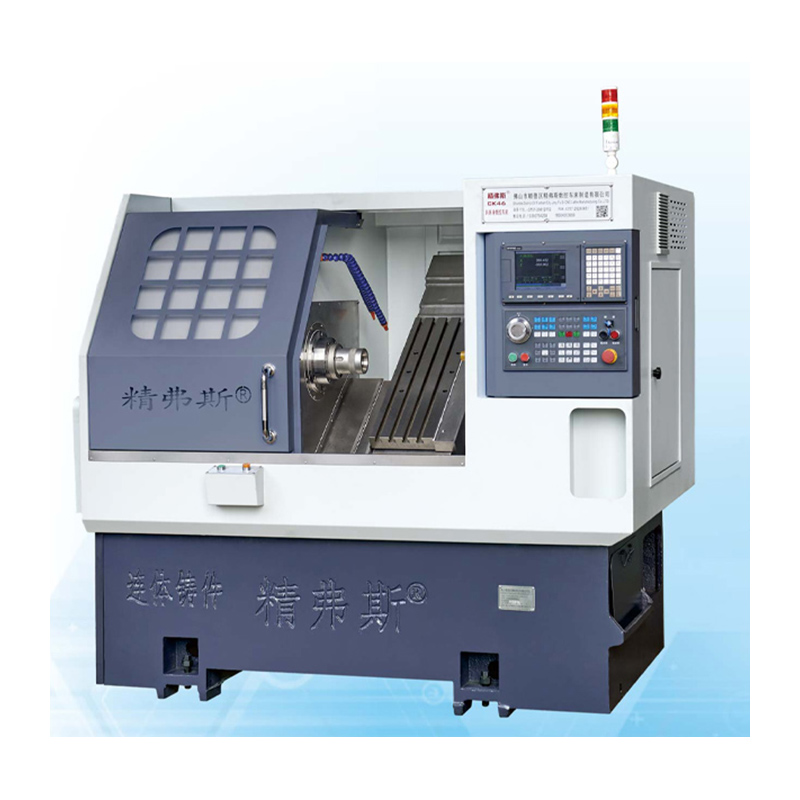

A slant-bed CNC lathe is a type of computer numerical control (CNC) lathe machine with a bed that is inclined at an angle relative to the horizontal plane. This design feature offers several advantages over traditional flat-bed lathes, making slant-bed lathes popular choices in modern machining operations, particularly in industries like aerospace, automotive, and medical device manufacturing.

Key Features of Slant-Bed CNC Lathes:

1. Bed Design:

- Slanted Angle: The bed is inclined at an angle typically ranging from 30 to 45 degrees, allowing chips and coolant to fall away from the workpiece and into the chip conveyor or collection system.

- Rigid Structure: Provides excellent stability and vibration damping, enhancing machining precision and surface finish.

2. Tool Setup and Accessibility:

- Ergonomic Design: The slanted bed design offers improved operator visibility and accessibility to the workpiece and cutting tools.

- Easy Chip Evacuation: Chips are directed away from the machining area, reducing the risk of chip buildup and tool damage.

3. Spindle Configuration:

- Horizontal Spindle: Typically, slant-bed lathes feature a horizontally mounted spindle, which facilitates efficient turning operations and allows for the use of various tool configurations.

- Powerful Drives: High-torque spindle motors enable heavy-duty cutting and machining of tough materials.

4. Tooling Flexibility:

- Tool Turrets: Equipped with tool turrets that can hold multiple cutting tools, allowing for rapid tool changes and increased machining efficiency.

- Live Tooling: Some slant-bed lathes feature live tooling capabilities, enabling milling, drilling, and other secondary operations in addition to turning.

5. Control System:

- CNC Control: Integrated with advanced CNC control systems that offer features like conversational programming, toolpath simulation, and automatic tool management.

- User-Friendly Interface: Intuitive controls and programming interfaces streamline setup and operation, reducing setup time and errors.

6. Automation Compatibility:

- Bar Feeder Integration: Capable of seamless integration with automatic bar feeders for continuous, unattended machining of long workpieces.

- Robotic Loading: Compatible with robotic loading and unloading systems for increased productivity and efficiency in high-volume production environments.

Advantages of Slant-Bed CNC Lathes:

1. Improved Chip Control:

- The slanted bed design allows chips to fall away from the workpiece and cutting tools, minimizing chip entanglement and reducing the risk of tool damage and workpiece defects.

2. Enhanced Rigidity and Stability:

- The rigid, inclined bed structure provides excellent support and damping characteristics, resulting in improved machining accuracy, surface finish, and tool life.

3. Operator Ergonomics:

- Operators benefit from improved visibility and access to the workpiece and cutting tools, reducing fatigue and enhancing safety during setup and operation.

4. Versatility:

- Slant-bed lathes offer versatility in machining a wide range of materials, from soft metals to hard alloys and exotic materials, making them suitable for diverse machining applications.

5. High Productivity:

- The combination of rapid tool changes, efficient chip evacuation, and advanced CNC control capabilities enables high-speed, high-precision machining with minimal downtime.

6. Cost Efficiency:

- Slant-bed lathes offer cost-effective solutions for small to medium-sized production runs, providing reliable performance and productivity at competitive prices.

Applications of Slant-Bed CNC Lathes:

1. Precision Turning:

- Ideal for producing complex cylindrical and contoured components with tight tolerances and fine surface finishes, such as shafts, bushings, and connectors.

2. Prototyping and Small Batch Production:

- Well-suited for prototyping and small batch production of machined parts across various industries, offering flexibility and efficiency in job setup and machining.

3. Automotive Manufacturing:

- Used for machining engine components, transmission parts, brake components, and other precision automotive parts requiring high accuracy and repeatability.

4. Aerospace and Defense:

- Critical for manufacturing aerospace components, including landing gear parts, engine components, hydraulic fittings, and structural elements, with stringent quality and performance requirements.

5. Medical Device Manufacturing:

- Employed in producing medical implants, surgical instruments, prosthetic components, and other precision medical devices requiring high-quality machining and surface finish.

Considerations for Selecting a Slant-Bed CNC Lathe:

1. Machine Size and Capacity:

- Choose a machine size and capacity that aligns with your specific machining requirements, including workpiece size, weight, and complexity.

2. Tooling and Workholding Compatibility:

- Ensure compatibility with the desired cutting tools, tool holders, and workholding devices, including chucks, collets, and fixtures, for efficient and accurate machining.

3. Control System Features:

- Evaluate the control system's features and capabilities, such as programming options, toolpath simulation, and connectivity for seamless integration with CAD/CAM systems and manufacturing networks.

4. Service and Support:

- Consider the availability of technical support, training, and aftermarket services from the machine manufacturer or distributor to ensure ongoing reliability and productivity.

5. Cost and ROI Analysis:

- Perform a cost-benefit analysis to evaluate the machine's initial purchase cost, operating costs, and potential return on investment (ROI) based on your anticipated production volume and business objectives.

Conclusion:

Slant-bed CNC lathes offer a range of advantages over traditional flat-bed lathes, including improved chip control, enhanced rigidity, operator ergonomics, and versatility in machining various materials and complex geometries. These machines are indispensable in modern machining operations, playing critical roles in industries such as automotive, aerospace, medical device manufacturing, and general engineering. By selecting the right machine configuration, control system, and tooling options, manufacturers can achieve high levels of productivity, accuracy, and efficiency in turning operations, ultimately driving success and competitiveness in today's manufacturing landscape.