Laminated Steel Film: The Versatile Material Revolutionizing Industries

2025-04-16

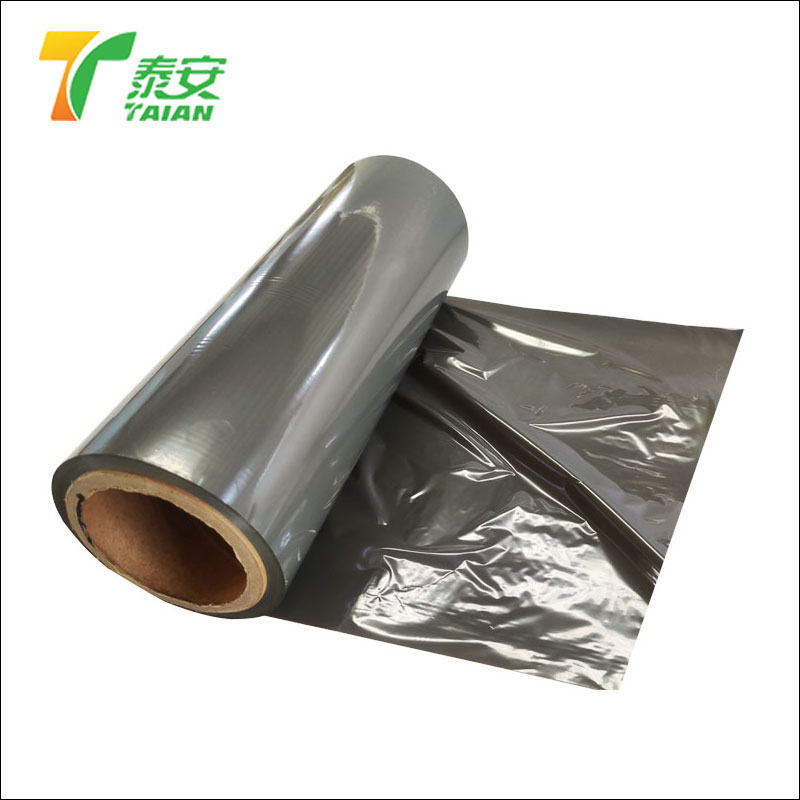

Laminated steel film, a cutting-edge material that combines the best of both worlds—steel’s strength and the flexibility of film—has emerged as an essential component across multiple industries. This material is not only known for its robustness but also its ability to offer superior protection, enhance product longevity, and maintain functionality in even the most challenging environments. In this blog, we will delve into what laminated steel film is, its benefits, how it is made, and its widespread applications in industries ranging from packaging to electronics.

What is Laminated Steel Film?

Laminated steel film is a composite material created by combining a thin layer of steel with a layer of film (usually polymer). The film is bonded to the steel through a process known as lamination. This method results in a material that possesses the strength, durability, and corrosion resistance of steel, while also benefiting from the lightness and flexibility of the film.

The resulting laminated steel film is incredibly versatile and can be used in a variety of applications, offering excellent protection, high tensile strength, and resistance to wear and tear. The bond between the steel and film is designed to withstand environmental stresses, ensuring the material remains intact under varying conditions.

How is Laminated Steel Film Made?

The process of making laminated steel film begins with selecting high-quality steel and film materials. The steel is typically coated with a protective layer to prevent rust and corrosion, while the film layer is chosen based on its specific qualities, such as flexibility, moisture resistance, and strength. The two layers are then carefully bonded together using specialized adhesives or heat and pressure to form a durable composite material.

Once laminated, the steel film is treated to ensure the surface is smooth, uniform, and capable of withstanding the intended application. Depending on the purpose, additional coatings or treatments may be applied to enhance the material's specific properties, such as UV resistance or anti-static properties.

Benefits of Laminated Steel Film

1. Increased Durability

The combination of steel and film makes laminated steel film an incredibly durable material. The steel provides superior strength, while the film offers flexibility and protection against moisture and other environmental factors. This makes it ideal for products that need to withstand harsh conditions, such as outdoor equipment or automotive components.

2. Corrosion Resistance

One of the major advantages of laminated steel film is its corrosion resistance. The steel layer is typically coated with protective finishes such as galvanization or other rust-resistant treatments. This means that the material can be used in environments prone to moisture, such as marine applications or outdoor installations, without worrying about rust or degradation.

3. Lightweight and Flexible

Despite being made of steel, laminated steel film is lightweight and flexible due to the polymer film layer. This makes it an ideal material for applications that require both strength and flexibility, such as in packaging or protective covers. The material can be easily shaped and molded to fit specific product requirements.

4. Cost-Effective

Laminated steel film is often more cost-effective than pure steel or other materials with similar protective properties. The process of lamination allows manufacturers to reduce the amount of steel needed in certain applications, while still maintaining the strength and durability required. This helps to lower production costs without compromising on quality.

5. Improved Aesthetic Appeal

The addition of a film layer to the steel offers the potential for better aesthetics. The film can be customized with various colors, textures, or finishes, enhancing the visual appeal of the final product. Whether it's for branding purposes, design, or simply to improve the overall appearance of the material, laminated steel film can meet diverse aesthetic needs.

Applications of Laminated Steel Film

Laminated steel film’s unique combination of properties makes it suitable for a wide range of industries and applications. Let’s take a look at some of the key areas where laminated steel film is making an impact:

1. Packaging

Laminated steel film is widely used in the packaging industry due to its durability, flexibility, and ability to protect products from moisture and external contaminants. The material is often used in packaging for food, electronics, and pharmaceuticals. It ensures that products remain intact and preserved throughout storage and transportation, providing an extra layer of security against potential damage.

2. Automotive Industry

In the automotive sector, laminated steel film is used in various applications such as protective covers, heat shields, and decorative trim. Its lightweight nature makes it a great choice for reducing the overall weight of vehicles, contributing to fuel efficiency. Additionally, the film’s resistance to rust and wear ensures that automotive parts maintain their functionality and appearance over time.

3. Electronics and Appliances

Laminated steel film is used in electronics and appliance housings, such as television screens, microwave oven panels, and computer cases. The material offers protection against physical damage, moisture, and dust, ensuring that the electronic components inside remain safe and operational. Its flexibility also makes it suitable for intricate designs and compact devices.

4. Construction and Building Materials

In construction, laminated steel film is used for roofing materials, window coverings, and flooring systems. The combination of steel’s strength and the film’s flexibility makes it ideal for these demanding applications, offering protection against the elements while maintaining durability. The material is also lightweight enough to ease handling and installation.

5. Consumer Goods

Laminated steel film is used in various consumer goods such as bottles, cans, and decorative packaging. The material can be used to enhance the design of these products while also providing a barrier against environmental factors such as moisture, oxygen, and UV rays. This makes it an excellent choice for items like beverage containers, cosmetics packaging, and household goods.

Environmental Considerations

While laminated steel film offers numerous benefits in terms of performance and durability, it's important to consider its environmental impact. Steel is a highly recyclable material, and the film layer can often be recycled depending on its composition. However, the environmental friendliness of laminated steel film depends on the specific materials used, the production process, and how it is disposed of at the end of its life cycle.

Manufacturers are increasingly working toward developing more sustainable versions of laminated steel film by incorporating eco-friendly films and adopting greener production methods. This helps reduce the overall environmental footprint of the material while still retaining its performance qualities.

Conclusion

Laminated steel film is an exceptional material that blends the strength of steel with the flexibility and versatility of polymer films. Its durability, corrosion resistance, and ability to protect products from environmental factors make it a valuable asset in industries ranging from packaging and automotive to electronics and construction. As technology advances and industries demand more efficient and sustainable materials, laminated steel film is poised to remain a key player in shaping the future of material science.

Whether you're looking for a material to improve product longevity, enhance performance, or simply offer protection, laminated steel film offers an innovative solution that meets a variety of needs across different sectors.