Trash Can Injection Molds: Revolutionizing Waste Management Manufacturing

2024-08-21

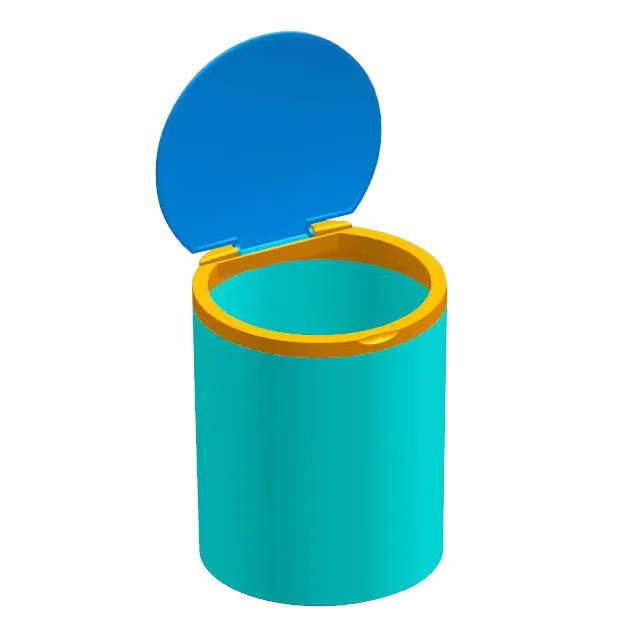

In the ever-evolving world of manufacturing, precision and efficiency are key to producing high-quality products. One area where these principles are critically applied is in the production of trash cans. The process of creating these essential items involves a sophisticated tool known as the trash can injection mold. In this blog, we’ll explore what trash can injection molds are, their benefits, and how they contribute to the manufacturing of durable and functional waste management solutions.

What Is a Trash Can Injection Mold?

A trash can injection mold is a specialized tool used in the manufacturing process of plastic trash cans through injection molding. Injection molding is a technique where molten plastic is injected into a mold cavity under high pressure. The plastic cools and solidifies within the mold to form the desired shape—in this case, a trash can.

The injection mold itself is a precisely engineered tool made from high-quality materials, often steel or aluminum, designed to create specific shapes and features in the trash cans. The mold is divided into two main parts: the core and the cavity. The core forms the interior shape of the trash can, while the cavity shapes the exterior.

Key Features of Trash Can Injection Molds

1. Precision Engineering:

Trash can injection molds are engineered with high precision to ensure that every trash can produced meets exact specifications. This precision is crucial for ensuring consistency in size, shape, and functionality.

2. Durable Materials:

The molds are typically made from durable materials such as hardened steel or aluminum, which can withstand the high pressures and temperatures involved in the injection molding process. This durability ensures a long lifespan and consistent performance.

3. Complex Design Capabilities:

Modern injection molds can incorporate complex features such as handles, lid mechanisms, and reinforcement ribs. This capability allows manufacturers to produce trash cans with advanced functionality and ergonomic designs.

4. High Production Efficiency:

Injection molding is a highly efficient process that allows for rapid production of large quantities of trash cans. The use of injection molds enables manufacturers to achieve high production rates while maintaining quality control.

5. Cost-Effectiveness:

Although the initial investment in injection molds can be significant, the efficiency of the process and the ability to produce large quantities of trash cans at once make it a cost-effective manufacturing solution in the long run.

6. Consistency and Quality:

The precise nature of injection molding ensures that each trash can produced is consistent in quality and free from defects. This consistency is essential for maintaining high standards and meeting customer expectations.

Benefits of Trash Can Injection Molds

1. Enhanced Durability:

Trash cans produced using injection molds are typically more durable and resistant to wear and tear. The strong plastic materials used in the molding process result in sturdy and long-lasting products.

2. Design Flexibility:

Injection molds offer significant design flexibility, allowing manufacturers to create trash cans with a variety of shapes, sizes, and features. This flexibility enables customization to meet specific needs and preferences.

3. Efficiency and Speed:

The injection molding process is known for its efficiency and speed. Once the mold is created, it can produce large volumes of trash cans quickly, reducing production time and increasing output.

4. Reduced Waste:

Injection molding minimizes material waste compared to other manufacturing processes. The precise control over material injection and cooling helps reduce excess material and improve overall resource efficiency.

5. Cost Savings:

Although the initial cost of designing and producing injection molds can be high, the cost savings achieved through efficient production and reduced material waste make it a cost-effective choice for large-scale manufacturing.

6. Improved Product Quality:

The use of high-quality molds and precise manufacturing techniques results in consistently high-quality trash cans. This reliability enhances customer satisfaction and reduces the likelihood of defects.

Applications of Trash Can Injection Molds

1. Residential Trash Cans:

Trash can injection molds are used to manufacture a wide range of residential trash cans, including those with different sizes, shapes, and features such as foot pedals or swing lids.

2. Commercial Waste Bins:

In commercial settings, injection molds are used to produce larger and more robust waste bins designed for heavy-duty use. These bins are often equipped with features that enhance their functionality and durability.

3. Industrial Waste Containers:

For industrial applications, injection molds create heavy-duty waste containers capable of handling large volumes of waste and resisting harsh conditions. These containers are built to withstand rigorous use and environmental factors.

4. Recycling Bins:

Injection molding is also used to manufacture recycling bins with specific compartments and features to facilitate waste separation and recycling efforts. These bins are designed to support sustainable waste management practices.

5. Specialized Trash Cans:

Custom injection molds can produce specialized trash cans with unique features or designs, such as those for medical waste, hazardous materials, or other specific applications.

6. Outdoor and Street Furniture:

Trash can injection molds are used to create outdoor trash receptacles and street furniture designed to withstand outdoor elements and high traffic areas.

Choosing the Right Trash Can Injection Mold

1. Evaluate Design Requirements:

Consider the specific design requirements for your trash cans, including size, shape, and features. Choose an injection mold that meets these requirements and allows for the desired functionality.

2. Material Selection:

Select high-quality materials for the mold that can withstand the pressures and temperatures of the injection molding process. Durable materials ensure a longer mold lifespan and consistent product quality.

3. Production Volume:

Assess the anticipated production volume and choose a mold that can accommodate your needs. High-volume production may require more robust molds capable of withstanding extensive use.

4. Consult with Experts:

Work with mold design and manufacturing experts to ensure that the mold is engineered to meet your specific needs. Their expertise can help optimize the design and functionality of the mold.

5. Consider Cost vs. Benefit:

Weigh the initial cost of mold design and production against the long-term benefits of efficient and high-quality manufacturing. The right investment can lead to significant cost savings and improved product quality.

Popular Brands and Models

Several companies specialize in the design and production of trash can injection molds, each offering unique features and capabilities. Some notable options include:

- Husky Injection Molding Systems: Known for their advanced injection molding technologies, Husky offers a range of molds designed for high efficiency and quality in producing trash cans.

- Milacron: Milacron provides injection molds with precision engineering and durability, suitable for various applications, including trash can manufacturing.

- Arburg: Arburg offers innovative injection molding solutions that enhance production efficiency and product quality, making them a popular choice for trash can molds.

Conclusion

Trash can injection molds represent a critical component in the manufacturing process of durable and efficient waste management solutions. Their precision engineering, design flexibility, and efficiency make them essential for producing high-quality trash cans and other waste containers. By understanding the benefits and features of injection molds, manufacturers can optimize their production processes and deliver products that meet the highest standards of performance and reliability. Embrace the power of injection molding and transform your trash can manufacturing with this cutting-edge technology.