Types of HDI Boards

2024-05-31

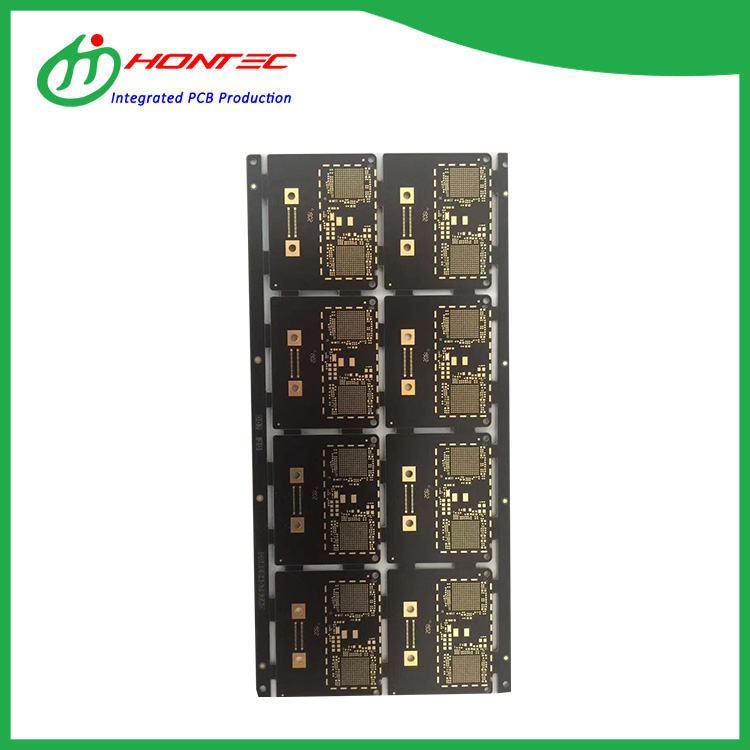

HDI (High-Density Interconnect) boards are a type of printed circuit board (PCB) that feature a higher wiring density per unit area compared to conventional PCBs. They are designed to accommodate more components and finer circuitry within a smaller footprint, making them essential for modern electronics where space is a premium. Here’s a detailed look at HDI boards:

Characteristics

1. Microvias: HDI boards use microvias, which are small holes with a diameter typically less than 150 microns, to connect layers within the PCB. These are smaller than traditional vias.

2. Laser Drilling: Microvias are often created using laser drilling, which allows for high precision and density.

3. Thin Layers: HDI boards generally have thinner layers, enabling closer placement of components.

4. Sequential Build-Up (SBU): Often constructed using a sequential build-up process, allowing for multiple layers of circuitry with microvias connecting them.

5. Fine Lines and Spaces: Features finer lines and spaces between conductive tracks, often in the range of 50 microns or less.

Types of HDI Boards

1. 1-Step HDI: Simple HDI board with a single layer of microvias.

2. 2-Step HDI: More complex, featuring two layers of microvias.

3. 3-Step and Higher: Even more layers of microvias, allowing for even higher component density and more complex interconnections.

Applications

1. Smartphones and Tablets: Essential for compact and high-performance mobile devices.

2. Wearable Technology: Used in smartwatches, fitness trackers, and other wearable devices.

3. Automotive Electronics: Critical for advanced automotive systems, including infotainment and safety systems.

4. Medical Devices: Used in compact and high-reliability medical electronics.

5. Aerospace and Defense: Employed in high-performance and space-constrained military and aerospace applications.

Advantages

1. Space Efficiency: Allows for more components in a smaller area, enabling miniaturization of electronic devices.

2. Performance: Improved electrical performance due to shorter signal paths and reduced signal loss.

3. Reliability: Enhanced reliability with reduced chances of defects due to precise manufacturing processes.

4. Weight Reduction: Helps in reducing the overall weight of electronic devices, which is crucial for portable and wearable applications.

5. Design Flexibility: Allows for more complex designs with advanced features in compact packages.

Manufacturing Considerations

1. Cost: Generally more expensive to produce than traditional PCBs due to advanced materials and processes.

2. Complexity: Requires sophisticated design and manufacturing techniques, often necessitating collaboration with specialized PCB manufacturers.

3. Material Selection: High-quality materials are needed to withstand the precision processes and to maintain the integrity of the fine features.

Design Tips

1. Use of Microvias: Optimize the use of microvias to connect layers efficiently without increasing complexity unnecessarily.

2. Stacked and Staggered Vias: Consider using stacked or staggered vias for better performance and reliability.

3. Signal Integrity: Pay attention to signal integrity issues by minimizing path lengths and using appropriate grounding techniques.

4. Thermal Management: Ensure adequate thermal management strategies are in place due to the high density of components.

Conclusion

HDI boards represent a significant advancement in PCB technology, offering substantial benefits in terms of space efficiency, performance, and design flexibility. They are essential for the latest generation of electronic devices where miniaturization and high performance are critical. Despite their higher cost and complexity, the advantages they bring make them indispensable in fields ranging from consumer electronics to aerospace. Proper design, material selection, and collaboration with experienced manufacturers are key to leveraging the full potential of HDI boards.