Why Is Aluminum PCB the Go-To Choice for Modern Electronics?

2024-12-26

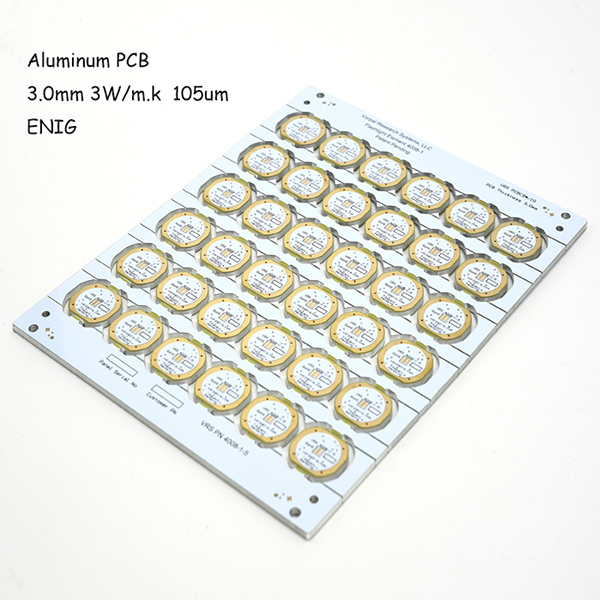

As the electronics industry continues to innovate, the demand for reliable, efficient, and heat-resistant materials is at an all-time high. Among the various options available, Aluminum PCBs (Printed Circuit Boards) have emerged as a game-changer. But why are they the preferred choice for modern electronics? Let’s explore their unique features, benefits, and applications to understand their rising popularity.

What Is an Aluminum PCB?

An Aluminum PCB is a type of circuit board that uses an aluminum base instead of the traditional fiberglass or epoxy base. It consists of three main layers:

1. Circuit Layer: A copper foil layer that facilitates electrical connections.

2. Dielectric Layer: A thermally conductive but electrically insulating layer.

3. Base Layer: An aluminum substrate that acts as a heat sink.

This unique structure makes Aluminum PCBs ideal for high-performance applications where heat dissipation is critical.

What Are the Benefits of Aluminum PCBs?

1. Exceptional Heat Dissipation

Aluminum has excellent thermal conductivity, allowing Aluminum PCBs to effectively dissipate heat generated by electronic components. This prevents overheating and prolongs the lifespan of devices.

2. Enhanced Durability

The aluminum substrate provides structural stability and resistance to physical stress, making these PCBs suitable for rugged environments.

3. Lightweight and Eco-Friendly

Despite being durable, aluminum is lightweight, which is ideal for compact and portable devices. Additionally, aluminum is recyclable, aligning with sustainable manufacturing practices.

4. Improved Electrical Performance

The dielectric layer enhances electrical insulation while maintaining thermal conductivity, ensuring reliable performance even in high-power applications.

5. Cost-Effectiveness

Aluminum is abundant and affordable, which reduces manufacturing costs compared to other heat-resistant materials like ceramics.

Where Are Aluminum PCBs Used?

1. LED Lighting

Aluminum PCBs are widely used in LED lighting systems due to their superior heat dissipation, ensuring consistent brightness and longevity.

2. Automotive Industry

Modern vehicles rely on Aluminum PCBs for headlight systems, engine controls, and sensors that require efficient thermal management.

3. Power Electronics

Applications like power supplies, inverters, and motor controllers benefit from the durability and thermal properties of Aluminum PCBs.

4. Consumer Electronics

From laptops to gaming systems, Aluminum PCBs ensure high performance and reliability in devices that generate significant heat.

5. Medical Equipment

High-power medical devices, such as X-ray machines and surgical lights, leverage Aluminum PCBs for consistent performance.

How to Choose the Right Aluminum PCB for Your Needs?

1. Thermal Conductivity

Opt for PCBs with high thermal conductivity if your application involves intense heat generation.

2. Layer Configuration

Single-layer, double-layer, or multi-layer Aluminum PCBs can be selected based on the complexity of your circuitry.

3. Surface Finish

Ensure the surface finish is compatible with your assembly process, whether it's HASL, ENIG, or others.

4. Custom Design Options

Look for manufacturers that offer custom designs to meet your specific requirements.

Is Aluminum PCB the Future of Electronics?

The versatility and performance of Aluminum PCBs position them as a cornerstone in the evolution of electronics. Their ability to handle thermal challenges, coupled with their affordability, makes them indispensable in high-performance and high-demand industries.

Conclusion

In a world where electronic devices are becoming more powerful and compact, Aluminum PCBs offer a perfect blend of performance, reliability, and cost-effectiveness. Whether you’re designing cutting-edge LED systems, automotive electronics, or consumer gadgets, Aluminum PCBs provide a solution that meets the challenges of modern technology.